Thank you Brynmorgen Press!

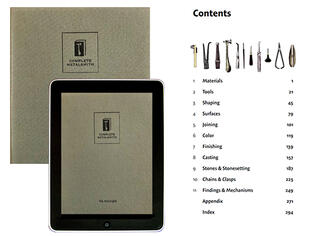

Tim McCreight has generously allowed us to post his Glossary of Jewelry Terms from the iBook edition of Complete Metalsmith by Brynmorgen Press. If you would like to have this handy bench companion in your library, you can easily download it from the Brynmorgen Press website.

A B C D E F G H I J K L M N O P R S T U W

Abrasives

Grains of tough material that are pressed against a softer material to shape it. Typically these are particles of minerals or manmade substances that are attached to a backing of paper, fabric or plastic. Sandpaper is a common example.

Air compressor

A machine that pulls air from the atmosphere with a pump to make it available as a pnuematic force. Most compressors include a tank to store the compressed air so it can be used when needed.

Alloy

A mixture of two or more metals. Common alloys are brass, bronze, sterling and karat golds.

Annealing

Annealing is the process of using heat to relieve stress in metal. Annealed metal is commonly called “soft” though the proper term is “malleable.”

The same word is used in glass to describe a slow carefully controlled cooling period after glass is formed.

Anodizing

Either of two kinds of process used to color metal with electrical current. In reactive metals like niobium, electric current is applied to clean metal through a bath which re- sults in oxide layers of specific thickness and color. In the case of aluminum, electric current creates a porous skin on metal that can then be colored with dye and sealed.

Anticlastic

Metal forming in which the radial and axial curves move in opposite directions. A saddle is an example of an anticlastic form. Anticlastic raising is usually done on a sinusoidal stake.

Aqua regia

The name of this most powerful acid translates from Latin to “Royal Water.” It is made by combining nitric and hydrochloric acids — but don’t do it. This is a highly dangerous corrosive material that dissolves even gold.

Argyria

A medical condition caused by overexposure to silver that turns the skin blue. The stain cannot be reversed.

Bail

A general term for loops, rings or other shapes that connect a pendant to a chain or cord.

Basse-taille

A type of enameling in which the floor of a recessed area is decorated, typically by engraving. When the section is filled with transparent enamel, the decoration is seen through the color. This is similar to the effect of looking at the bottom of a swimming pool. Pronounced BAS ty.

Bezel

A rim of metal that surrounds and secures a gem or the crystal of a watch.

Bezel Pusher

A tool used to press a bezel over a stone. The basic design is a squat tool with a bulbous handle and a short rod of steel or brass. The end should be smooth but not polished; clean up regularly with fine sandpaper to provide a little tooth.

Brazing

A form of joining in which a metal with a melting point very close to the parent metal is fused across a joint. In steel work, brazing refers to the use of brass as a joining metal. What we commonly call silver soldering is more accurately called silver brazing.

Brown & Sharpe (B&S)

Also called the American Wire Gauge (AWG). A system of measurement specific to non- ferous metals such as silver, gold, copper and brass. The system runs from 1 (a little more than a quarter of an inch) to 40 (thinner than a sheet of paper). By convention, jewelry metals are usually sold only in the even numbers. The most commonly used sizes for jewelry are 10, 12, 14, 16, 18, 20, 22 and 24, though of course there are exceptions.

Burnishing

A finishing process of rubbing a softer metal (such as silver) with a harder material (such as steel or agate).

Burnout

A step in the lost wax casting process when a mold is evacuated by melting out the wax model.

Computer Aided Design (CAD)*

CAD is the use of computer systems to assist in the creation, modification, analysis, or optimization of a design. -wikipedia

Computer Aided Manufacturing (CAM)*

CAM is the use of computer software to control machine tools and related machinery in the manufacturing of work pieces. -wikipedia

Carpal Tunnel Syndrome (CTS)

One of a group of medical conditions collectively called Repetitive Stress Injuries (RSI). Carpel tunnel is located in the wrist and leads to tingling, lack of strength and discomfort.

Casting

Techniques that pour or inject molten material into a mold. There are many forms of casting which is an ancient process. The results of these processes use the same word, such as, “These are high quality castings.”

Centrifugal Casting

A casting process in which centrifugal force is used to force molten metal into a mold. The most common device is a steel bar mounted onto a strong spring. When wound and released, the bar rotates quickly, throwing molten metal outward and into a mold.

Champlevé

A type of enameling in which enamel is fused into recessed sections of metal. Similar to basse-taille but in this case the floor of the recess is not decorated and opaque enamel is often used. Pronounced SCHOM la vay.

Chasing

A technique of using short steel punches to decorate and refine metal. Often used in conjunction with repoussé.

Cloisonné

A type of enameling in which compartments (“cloisonnes” are constructed, usually with thin strips of wire set on edge. These are then filled with enamel that is fused in place.

Coefficient of expansion (COE)

A precise measurement of the degree to which a material expands or contracts during heating and cooling. This is critical because when glass with different rates are combined they can crack or shatter as they cool.

Cold Connections

A casual term that refers to mechanical methods of joining parts together. Examples of cold connections are rivets, tabs, screws and clips.

Confirm

In fold forming, this refers to pressing a folded edge. The process is analogous to sliding your finger along a folded paper to make the crease sharper. Confirming can be done with a hammer, a mallet or in a rolling mill or hydraulic press.

Crimping

A process used in the early stages of raising to quickly develop a volumetric form.

Dapping

A process of pressing metal (usually a disk) into a hemispherical die with a spherical tool called a dapping punch.

Depletion Gilding

A process of creating a purer alloy on the surface of an object by leaching out the base metal of the alloy, typically with acid.

Dichroic Glass

Ornamental glass in which layers of various minerals and oxides create a range of shift- ing bright colors.

Die Forming

A family of techniques in which sheet metal is pressed against rigid dies to give if form.

Dies

Broadly, any object that gives its form to another is a die. This would include gelatin molds, cupcake pans and butter molds. In metalworking, most dies are made of hardened steel and involve pressure to form sheet metal. A specific kind of die called a drawplate is used to make wire thinner and to change its cross section.

Diffusion

The process of intermingling metal parts at the crystal level to effect a joint. Diffusion is central to the techniques of granulation, keum-boo and mokume gane.

Draw plates

Dies with a tapering hole used to make wire thinner and, at times, to change its cross section. Most draw plates are a rectangular bar of steel but some dies are individual disks with a single hole.

Elastic Deformation

What happens to a material when force is supplied only to the degree that the material can return to its original form. The opposite of this is “plastic deformation,” the degree of pressure needed to cause material to distort to the point where it won’t bounce back.

Electroforming

A process in which electrical current passing through a bath causes the deposition of metal onto a conductive form.

Electroplating

The process of using an electrical current to cause one kind of metal to transfer to the surface of another kind of metal. An example is gold plated jewelry, where a base metal object appears gold because of a thin layer of the precious metal.

Electrostripping

Electrostripping uses an electric current to remove metals selectively. Work is placed in a solution and attached to the positive pole of a battery or current generator. A piece of an appropriate metal is attached to the negative pole and both pieces are immersed in a solution. When the current is turned on, metal goes into solution form the anode and is drawn from the solution onto the base plate at the cathode. This process can be initiated on a small scale using only heat and household chemicals.

Enameling

An ancient technique in which powdered glass is fused to metal at relatively high temperatures. This is sometimes referred to as “vitreous enameling” to distinguish it from the modern faux enamels that substitute resins or paint.

Engraving

An ancient technique in which sharp steel chisels are used to carve into metal. Traditionally this was done by hand but now it can also be done with a pneumatic tool.

Etching

Removing material with an acid. In metalsmithing this usually refers to a process of selectively removing metal from a surface to create pattern or image.

Eutectic

The point in an alloy when the liquidus and solidus are the same. When reaching a specific temperature, a eutectic alloy passes directly from solid to liquid (or liquid to solid) without going through an intermediary slushy stage.

Firescale

A dark oxide that forms inside a metal object. This most frequently refers to a stain seen in sterling and low karat gold alloys.

Flexible Shaft Machine

A compact machine that consists of an electric motor, a hand piece and a flexible cable in a sheath that connects the too. “Flex shaft” for short, this tool is used by jewelers for drilling, grinding, sanding and polishing.

Flux

Any chemical that prevents the formation of oxides during a soldering process.

Fold forming

A family of metal forming processes used to develop form and texture. There are many variations, but in general they all involve folding a piece of metal, tightening the fold, then opening the form.

Forging

An ancient technique of shaping metal by hammering. In the case of ferrous metals, this is done when the metal is red hot. Nonferrous metals are usually forged at room temperature.

Fusion

Bonding together at temperatures at or above melting point.

Gauge Plate

A steel disk with carefully calibrated opening around the circumference that measure the thickness of sheet and wire.

Gold-filled

A bi-metal in which a layer of gold is bonded onto silver or a base metal then compacted or drawn to a final dimension.

Grade Rolling

A process of using a rolling mill to selectively thin a sheet of metal. The most common uses are to create a gradual thinning in preparation for forming a spiculum. The same result can be accomplished by planishing but the same term is usually used.

Granulation

An ancient technique in which very small spheres are attached to a surface as ornament. In proper granulation the filler that joins the parts is so small it is invisible to the naked eye, creating the illusion that the tiny balls are simply set in place.

Gravers

The hardened steel gouges used in engraving. Also called “burins.”

Hydraulic Press

A sturdy steel structure in which a hydraulic car jack is used to apply local pressure on a die.

Investment

A plaster-like material used in lost wax casting.

Jigs

Tools used to simplify bending, joining or cutting. In addition to improving efficiency, jigs create uniformity between parts.

Jump Rings

Metal rings used to make chains or to connect parts, for instance attaching charms or a pendant.

Karat

This refers to the proportion of pure gold in an alloy. The number 24 is assigned to pure gold, meaning that an alloy containing half gold is called 12 karat. In the UK this means the same but is spelled “carat.”

Keum-boo

An ancient Korean process of fusing thin sheets of pure or nearly-pure gold onto silver for decoration.

Lost Wax Process

A technique in which a wax model is captured in a mold of mud or (modern) investment. When the mold is heated, the wax melts away (“lost”), leaving a cavity that is then filled with molten metal. Because the mold must be broken to retrieve the cast- ing, this is a “waste mold” process.

Malleability

The ability of metal to be bent and formed.

Mallet

A hammer-like tool with the head made of wood, plastic or leather. Mallets bend and form metal without thinning it the way a steel hammer will.

Mandrels

Tools (typically tapered rods) used to impart their form on malleable metal. A ring mandrel, for example, is used to make a ring band round.

Metal Clay

A modern art material composed of microscopic metal particles mixed into an organic binder to create a moldable substance. After modeling and drying, a metal clay object is heated to burn away the binder and fuse the particles together.

Model

An exact likeness of an object to be cast. Depending on the technique, this can be made of wax, plastic, wood or metal. A mold is made from the model, whose shape is then copied when the mold is filled. Another word sometimes used for this is “pattern.”

Mohs Scale of Hardness

Generalized scale that uses ten specific minerals to rank hardness (#1 = talc; # 10 = diamond). Samples of a given hardness will scratch those with a lower number and be scratched by those with a higher number. The system is convenient for field research but lacks scientific precision.

Mokume (mo-ku-may)

A Japanese technique in which layers (sometimes hundreds) of contrasting metals are distorted and worked to show complicated organic or geometric patterns. Also called “mokume gane” (GAN ay) which translates to “wood grain”).

Niello

A material and technique of fusing a low-melting lead oxide onto metal for decoration. The result is a shiny dark gray inlay.

Oxidation

What happens when oxygen bonds with a material. In general this is something to be avoided. When soldering, too much oxygen in the joint will inhibit solder flow. When melting metals for casting, excess oxygen may create porous metal.

Patinas

Colored layers on metal. While these occur naturally, the term more often refers to treatments done in the studio to improve the appearance of a metal object.

Pavé

A technique of setting many small stones close together; most often seen with diamonds. The result is that the surface is “paved” with gems like a cobblestone walk.

Phase Diagram

A scientific form that shows the melting points and characteristics of metals and alloys. An arcing line traces the solidus and liquidus points of an alloy as the relative amounts of the constituent metals changes. Diagrams for two metals are rectangular and diagrams showing three metals are triangular.

Pickle

An acidic solution used to clean metal after it has been heated. Historically strong acids were used but modern pickles rely on sodium bisulfate or citric acid because they are less dangerous to people and the environment.

Piercing

Sawing, particularly when cutting out an interior space.

Planish (planishing)

The process of striking metal with a polished hammer to smooth its surface. Depending the degree of work and the shape of the hammer, this can be a final finish.

Plastic Deformation

This term describes what happens when the force applied to a sample is sufficient to effect a permanent change. This is the opposite of “elastic deformation” which is what happens when a material returns to its original shape.

Plique-á-jour

A type of enameling in which openings in a metal form are filled with enamel powder that is then fused. This is often visualized as a stained glass window.

Punch

A short steel tool, usually struck with a hammer to create form, texture or lines in metal. Punches are usually described with the process for which they are used, as in, dapping punches, chasing punches and repoussé punches. They can be purchased or made in the studio as needed.

Raising

A metalworking process in which malleable sheet is hammered over a steel form to transform a flat sheet into volumetric form.

Reactive Metals

A family of six tough gray metals: niobium, titanium, tantalum, zirconium, tungsten and hafnium. Their light weight causes them to be used in industry and sporting equipment. For jewelers, the attraction is the range of permanent colors that can be achieved through anodizing.

Recrystallization

The ability of most metals to reconfigure their crystalline structure at annealing temperatures. This is what makes it possible to work metal into complex forms.

Repetitive Strain Injuries (RSIs)

A family of medical problems caused when simple activities are repeated too much. Fortunately, these can be reduced or avoided altogether through simple exercises.

Repoussé

An ancient technique that uses short steel rods (punches) to form metal as it is being held against a firm but yielding material such as pitch or wax.

Scoring

Carving a groove into wire or sheet to facilitate bending.

Shell Structures

A term used to denote handmade metal forms, especially those made through anticlastic raising.

Sinking

A simple forming process in which a sheet of metal is hammered into a groove or bowl- shaped cavity.

Spiculum

A flared tube—think of the trumpets used to announce the arrival of a king in cartoons and old movies. Spiculums can be made in any size and may be straight or curved. Most cases include grade rolling so that the relationship of thickness to diameter remains constant.

Sprue

At various times in the casting sequence, this refers to (a) a wax rod, (b) the passage through a mold left when the wax is removed and (c) the metal that fills that space when the mold is filled. The sprue supports work in the mold then later provides the entry for metal into the mold. After casting, sprues are cut off.

Stakes

Tools made from wood, plastic and steel used to form, refine and planish metal. Broad categories, named for their shape, are T-stakes, mushroom stakes and spoon stakes.

Stretching

A technique in which thick metal is pinched between an anvil and a hammer with a curved face, causing it to arc upward, creating a concave form. In addition to requiring very little forming equipment, this technique is practiced because of the thick rim that is created.

Synclastic

A form or surface in which the axial curve and the radial curve bend in the same direction. The simplest example is a bowl; a synclast will hold water.

Tumbling

A finishing process in which objects are put into a plastic or rubber container along with steel balls or shapes of hard plastic that contain grit to simulate sanding, burnishing or buffing. Most commercial jewelry is run through a series of tumbling media from coarse to fine to create a smooth shiny polish.

Ultrasonic

A machine that uses high energy waves traveling through a bath of soapy water to clean jewelry and other small parts.

Urethane

A kind of rubber used in die forming. The toughness and flexibility of urethanes are identified by a unit called a durometer. The higher the number harder the material.

White Metals

A casual term for metals that have similar appearance, melting points and properties. Included here are lead, bismuth, antimony and cadmium.

Work-hardening

Work-hardening occurs when metal is bent, hammered or twisted. The potential mallelability (which differs among metals) is “used up” resulting in a metal that is brittle and difficult to work. For most metals, annealing will allow the internal structure to re- crystallize which restores malleability.

Work hardening is a negative in some instances, for instance when further work is needed. At other times, objects are intentionally left in their work-hardened state to provide extra strength.