Solder Savvy: A Deep Dive Into the Art + Science of Soldering - Part 1

Soldering is a fundamental metalsmithing skill, but arguably one of the hardest to master. Nothing is more frustrating than having a joint fail or worse – melting a piece you have spent hours on. Don’t let your designs be limited by intimidation! Through this intensive course, students will learn what is needed to achieve consistently strong, seamless joints and gain confidence to tackle their toughest projects!

This 4-week course is split into two modules, at two sessions (weeks) per module. Each module will focus on a specific aspect of soldering, from choosing the right equipment and supplies to cleaning up once the solder job is done (see below for a list of topics covered in each session). Be sure to register for both modules for an all-inclusive soldering overview. Safe practices and safety equipment will be addressed throughout.

Each module comprises a combination of lecture, demo, and Q&A, with opportunities for those already using torches to share their trials and triumphs. Color handouts will be provided, but notetaking is highly encouraged throughout this information-packed course.

Whether you are thinking about buying your first torch or want to take your soldering to the next level, this comprehensive curriculum has something to offer makers at all levels.

Part 1 (module one) Topics:

Session 1 - Choosing the Right Torch + Safe Operation

-

What is soldering, and how is it different from brazing, welding, or fusing?

-

Safety Overview (ventilation, PPE, fire, explosion, leaks)

-

Choosing the right ventilation for your space

-

-

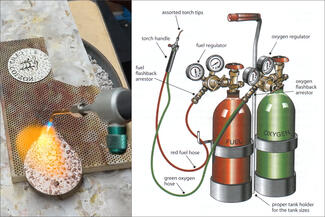

Torch Types & Tips

-

Fuel Gases & Compressed Air/Oxygen

-

Transporting & Storing Bottled Gases

-

-

Strikers

-

Regulators & Hoses

-

Torch Holders

-

Demos:

-

Torch Setup

-

Leak Testing

-

Turning the System On & Shutting it Down

-

Flame types and applications

-

-

Session 2 - Soldering Station Supplies + Setup

-

3 Things Solder Needs to Make a Good Joint

-

Oxidation & Firescale (and how to avoid them)

-

Pickles (traditional formulae and citric)

-

Fluxes, Pre-Fluxes & Anti-Fluxes (which is best for which metal or application)

-

Furniture, Fixtures, Props and Jigs

-

Tweezers and Picks

-

Clamps and Bindings

-

Demos:

-

Soldering Station Setup

-

Side-by-Side Torch Comparisons

-

Side-by-side Flux & Pickle Performance

-

Customized Setups for Specific Tasks

-

-

Click HERE to read up on Solder Savvy: Part 2.

Meet the instructor

Kristin Mitsu Shiga is a hapa metalsmith, educator and arts administrator who has played a variety of roles in the arts since 1992. You may recognize her as the ringmaster of Metalwerx’s Virtual Spring Symposium!

From a long line of educators, Kristin is passionate about teaching and has had the opportunity to share with students at venues all over North America including Penland, Arrowmont and Haystack Mountain schools of craft. Her proudest achievements have been establishing nonprofit metalsmiting studios and programs that continue today in New York (OCM BOCES), Oregon (Multnomah Arts Center), and Hawai'i (Donkey Mill Arts Center).

As a maker, Kristin pursues projects that tell a story and actively engage her audience. Her solo work centers around one-of-a-kind wearable art and holloware with an aesthetic that has been described as a "marriage between her Japanese heritage and influences from her early explorations in architecture and the Modernist design movement." Her ongoing series, "Unfinished, Damaged & Broken" explores the significance of age and wear on common objects while protecting, bolstering or celebrating their hard-won imperfections.

Kristin has shown her work internationally, and is included in several notable collections, including the Kamm Artful Teapot Collection and the Permanent Collection of the White House. You will find her work published in numerous books and magazines, including Art Jewelry Today, The Art of Enameling, Metalsmith’s 2017 Exhibition in Print, and several of Lark’s 500 Series books. Learn more about Kristin’s past work on Oregon Artbeat (segment originally aired in 2010).

Materials & Tools

This course will be demonstration focused and does not require student to get supplies prior to class. The instructor will provide an extensive document highlighting all the tools and supplies that will be covered in class, which will sent to students during the class.