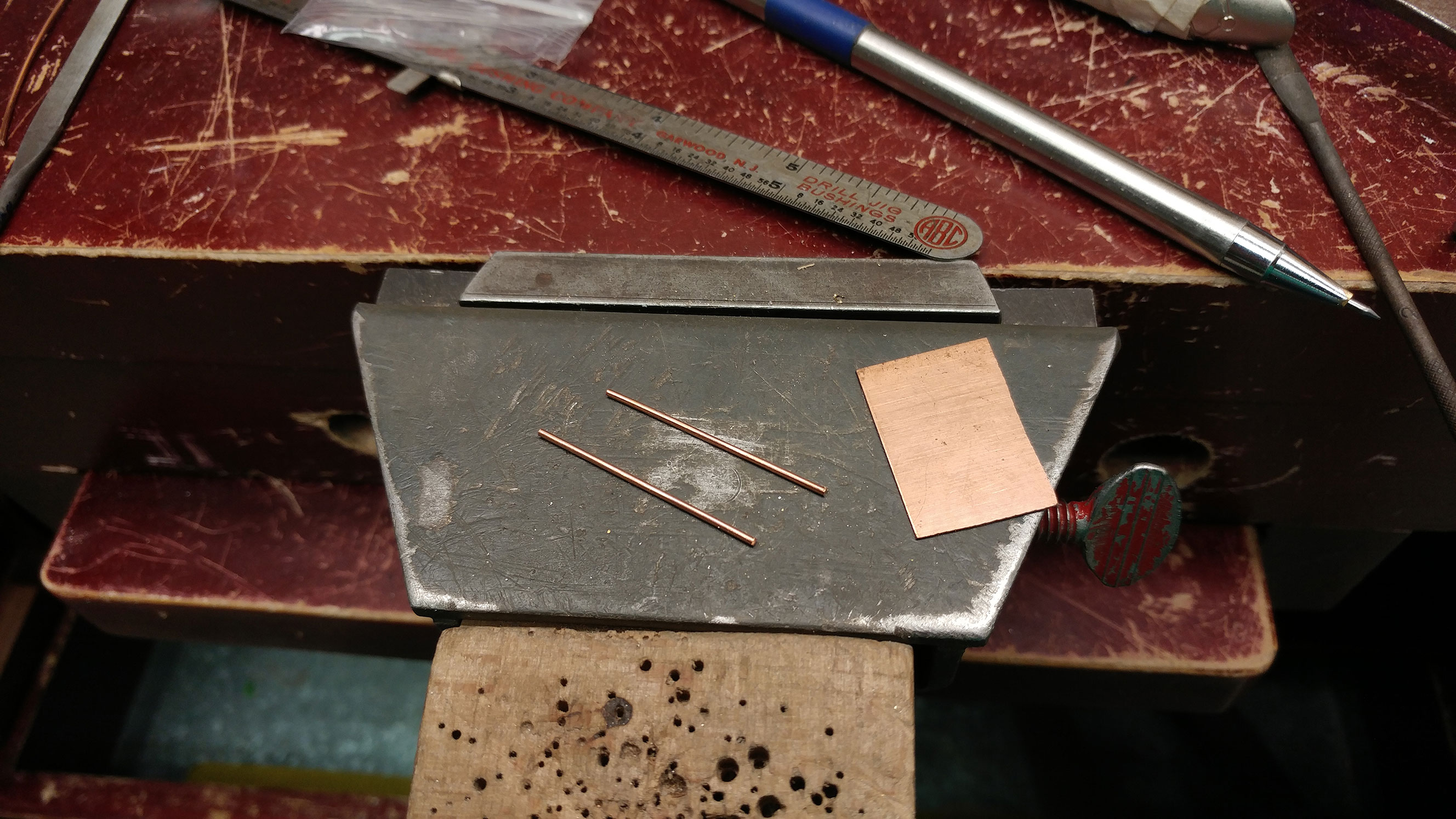

Step 1: Cut two pieces of wire to the same length. The length of these two wires will determine how big the bale is. For this example I am using two lengths 20g copper wire that are 30mm long.

Step 2: Mark off the middle point of each of these wires, and give them a bend with two parallel pliers. The angle you bend here will determine how wide and tall the bale is.

Step 3: Make sure both wires are even, and then sand the tips so that they fit flush together.

Step 4: Cut out a rectangular piece of sheet metal that is a thinner gauge than the wire. I am using 22g in this example. You will be soldering the "diamond" you have made to this sheet, but not before you sand a flat spot on each wire. The faces which will be contacting the sheet metal.

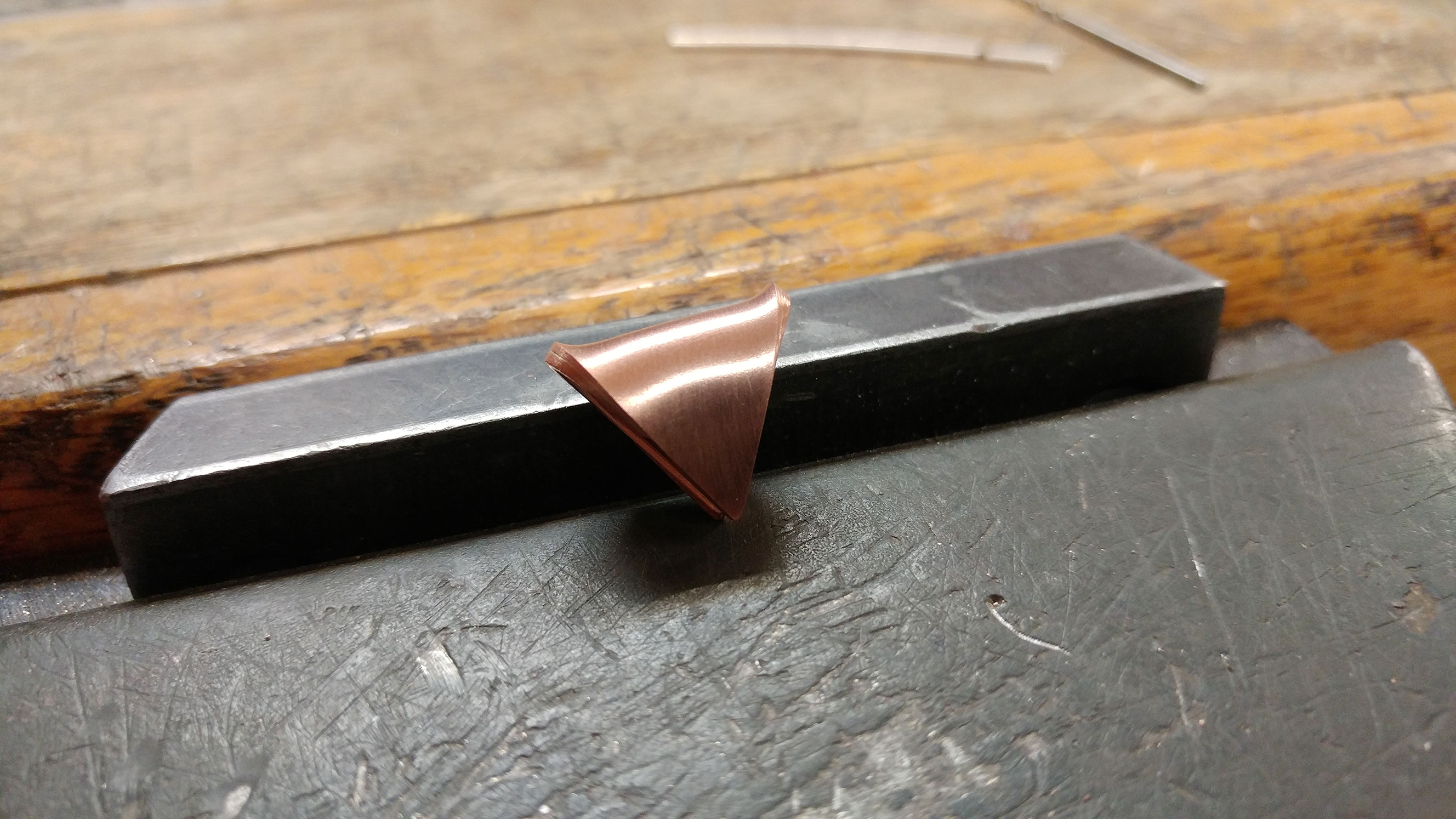

Step 5: Once it is soldered, you will cut away the excess metal, file and sand the sides so that they are smooth and even, and polish the flat side to a desired finish. Then you take your two parallel pliers and bend the bale so that the wire is facing inside. You will want to put a small piece of leather between your pliers and the metal to avoid marring the bail.

Step 6: There will come a point where your pliers cannot bend the bale any further. From here, simply place it on a wooden surface and tap the tips of the bale with a mallet to close them the rest of the way. Be sure to hit evenly on both sides: if you tap one side four times, tape the other four times as well.

Step 7: Your bail is done! Try mixing and matching metal thicknesses! You can get a more dramatic dip in the middle of the bale by using a wire that is even thicker than the sheet metal.